Modern Cafeteria, Canteen and Restaurant Serving Counter Designs Don’t Have to Break the Bank Which…

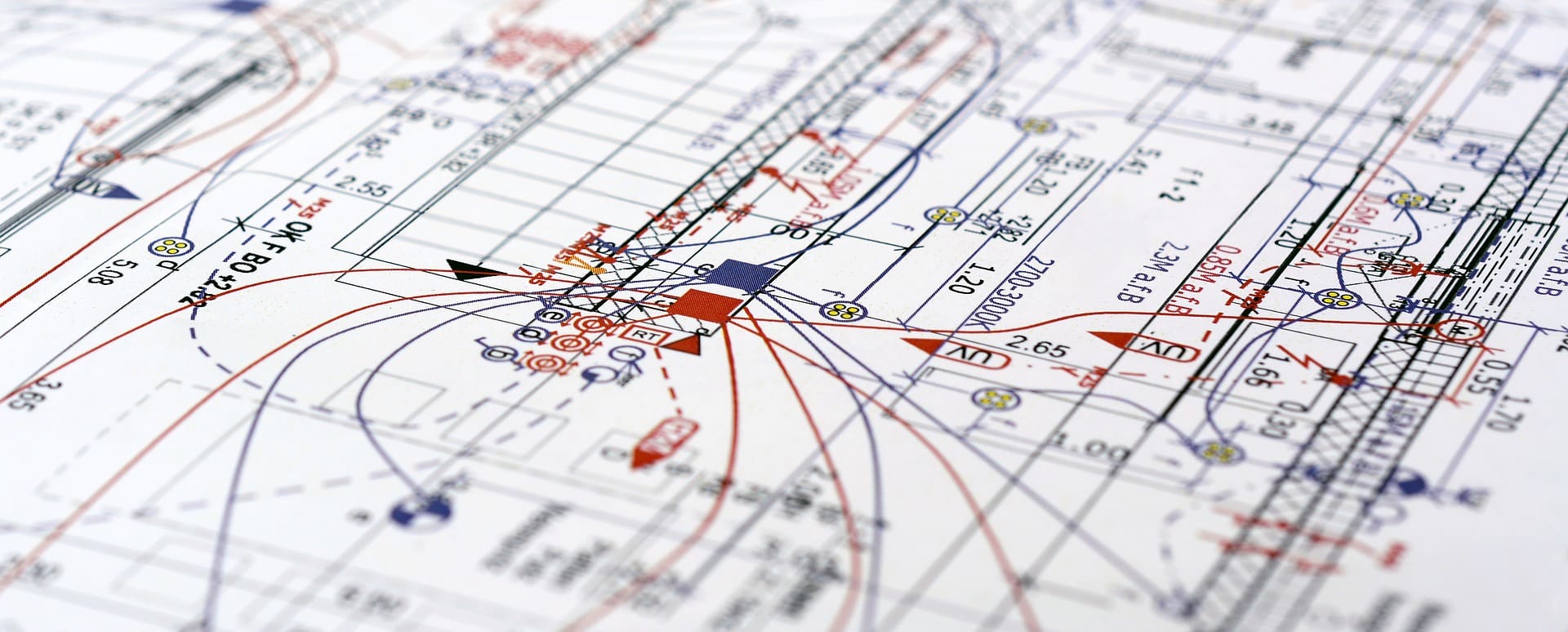

Reduce utility costs with these plumbing & electrical design tips

Whether you’re considering new construction or a facility renovation, the array of costs can be great. With the number of design, material and equipment options, decisions regarding utilities can often be based on what recommendations buyers are given first. Buyers know if they are going to try to save money, they shouldn’t try to do it by using cheap electrical or plumbing work. However, there are still ways to save money on utilities.

Here are a few points of servery utility design that can help save operators money at the time of purchase — as well as in the long run.

Electrical tips

- Purchase serving equipment from a manufacturer that utilizes factory-installed, pre-wired subpanels. This will mean fewer connections to the equipment for customers to worry about at the point of installation and will help control electrical costs over the equipment’s life.

- Use an equipment manufacturer who will consolidate the internal wiring of equipment by using a central junction box. For example, outlets along the backsplash of the equipment can be wired to this box. Doing so for each section of equipment will limit the number of overall connections, leaving only five connections for the electrician to install instead of 15, for instance.

- In case the facility has limited points of power, or to avoid installing multiple electrical stub-up connections in the floor, mobile or modular counters can be purchased and daisy-chained together. This will provide a one-point connection through a single stub-up in the floor or a vertical soffit connection on a wall or post.

- Check that the wiring being installed meets the facility’s power requirements. For example, if the equipment being installed requires 200 amps of single-phase power you might be able to use higher performance and lower cost 3-phase power. If 3-phase power is not available, the next best option is to reduce the overall power and use equipment like heated wells, lamps and drawer warms — all low-voltage equipment. Hot wells, for example, can range from 1500 watts per well to 500 watts per well, which makes for a tremendous difference in total amp draw.

Plumbing Tips

- When your drop-in units are being manufactured, ensure that they are all pre-manifolded with just one connection point. This means all the connections will flow to one single drain instead of individual drains for each drop-in. Purchasing equipment that has not been manifolded with one connection point will mean performing that work in the field, equaling higher costs at the time of installation.

- If water costs in the operating area are high, consider using hot wells that can run dry. While the drainage will still need to be hooked up, being able to avoid water costs — as well as waste water costs — can help operators save a bit extra each month.

- There are ways to consolidate equipment entirely — requiring fewer plumbed connections. For businesses that need three hot wells and three cold wells, it’s worth considering a four-well QuickSwitch unit and seeing the significant savings that can be derived from combining equipment to one that can perform multiple tasks.

Bonus Tips

- Future proof your facility, if possible. If building a facility from scratch, be sure to include extra outlets, water connections and/or floor drains. These are far easier to install and cost less to do at the initial time of construction than installing them after the fact.

- Meet early with plumbers and electricians in the construction or renovation process. This will help the project run significantly smoother and allow for more time to figure out any design challenges. They will also be able to help make recommendations that will make any future expansion possible and easier.

Interested in more serving equipment options that can help your dining hall, cafeteria or food hall projects become more efficient with plumbing and electricity? Be sure to visit our serving technologies page for a complete list of LTI equipment.